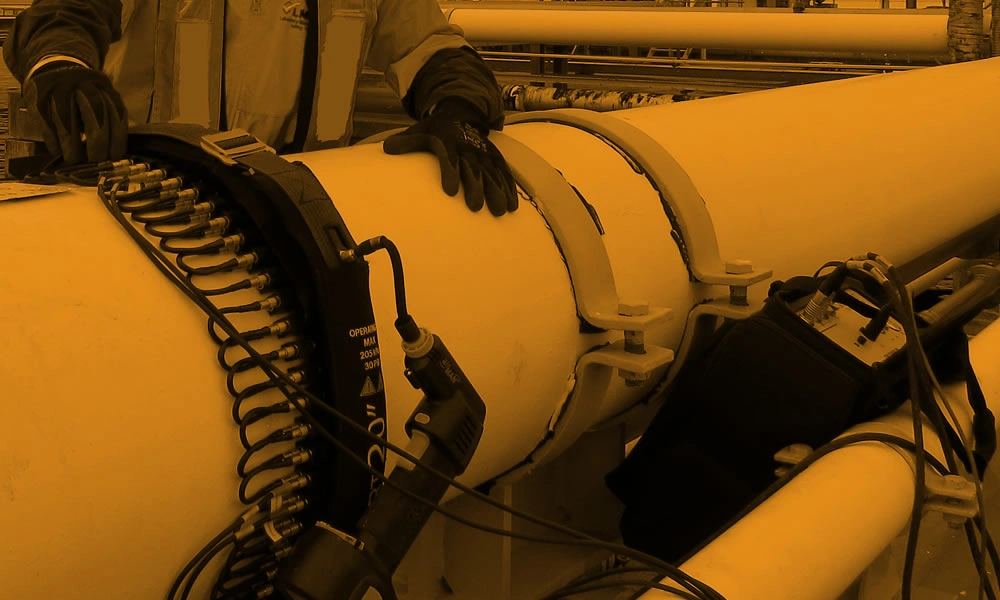

Total focusing method (TFM) / Full Matrix Capture is a significant technological advancement in the non-destructive testing (NDT) industry. The TFM method represents a significant advancement in phased array ultrasonic testing (PAUT) technology. However, some PAUT practitioners may remain perplexed about TFM and its relationship to full matrix capture (FMC), as well as the differences between traditional PAUT and TFM/FMC processing.

When compared to standard phased array ultrasonic testing, the total focusing method algorithm can provide greater clarity and precision. To understand how it is necessary to first understand what information is lost during a standard phased array.

A “sector scan” method of inspection is used in standard phased array technology. First, the software selects a focal law-the calculation that will be used to interpret scan results. The array then pulses receives a signal and digitizes the signal. It employs the delay law to combine the signals from each receiver, discarding raw data.

The instrument then adjusts the beam angles, computes a new focal law, and pulses again to repeat the process. Each sector scan’s results are summarised to create a Sectorial, Linear, or Compound scan image.

The total focusing method algorithm, on the other hand, does not summarise. Data from each transmitter/receiver in the array is digitized and saved separately, a process known as Full Matrix Capture (FMC). The software generates a focal law for each pixel in the image based on this information. Analyzing FMC data with TFM focal laws provides a different perspective than conventional phased array analysis.

TFM does not replace the conventional Phased Array. It is, however, a powerful tool for augmenting PAUT, improving image resolution, and characterizing smaller flaws.

Using the total focusing method can assist technicians in identifying small defects or flaws in difficult inspections. While standard PAUT remains the code and regulation method, TFM can still assist industries in improving safety and maintenance results. Based on case studies, here are some examples of useful TFM applications:

| ISSUE | INDUSTRIES | NEEDS |

|---|---|---|

| Hydrogen Induced Cracking | Wet H2S refinery environments | This type of cracking can occur at low temperatures. Standard PAUT may not show stepwise internal cracks between hydrogen blisters. |

| High-Temperature Hydrogen Attack | Refineries, Petrochemical, Chemical | Voids in steel < 0.1mm in the early stages of HTHA are difficult to detect without the advanced capabilities of TFM. |

| Dissimilar Metal Welds | Nuclear, Oil & Gas | Complex geometries, multiple acoustic interfaces, and austenitic structure propagation issues create difficulty for standard PAUT. |

| Hydrogen Induced Cracking | |

|---|---|

| Wet H2S refinery environments | |

| This type of cracking can occur at low temperatures. Standard PAUT may not show stepwise internal cracks between hydrogen blisters. | |

| High-Temperature Hydrogen Attack | |

|---|---|

| Refineries, Petrochemical, Chemical | |

| Voids in steel < 0.1mm in the early stages of HTHA are difficult to detect without the advanced capabilities of TFM. | |

| Dissimilar Metal Welds | |

|---|---|

| Nuclear, Oil & Gas | |

| Nuclear, Oil & Gas | |

Using TFM to identify issues early on allows managers to plan repairs or replacements well ahead of time, ensuring the most efficient allocation of maintenance resources. Swapping unplanned downtime for scheduled maintenance keeps operations running smoothly, and detecting failure points early protects both workers and the bottom line.

HEAD OFFICE

P.O. Box: 84711,

106, Al Midfa Building,

Al Qusais Industrial Area 4,

Dubai UAE

©2025www.aqualisgroup.com. All Rights Reserved.

©2025www.aqualisgroup.com All Rights Reserved.