Ultrasonic corrosion mapping is an intrusive inspection technique that uses ultrasonic reflection to map material thickness. Variations in material thickness caused by corrosion can be identified and graphically represented as an easy-to-understand image.

Ultrasonic corrosion mapping is an intrusive inspection technique that uses ultrasonic reflection to map material thickness. Variations in material thickness caused by corrosion can be identified and graphically represented as an easy-to-understand image.

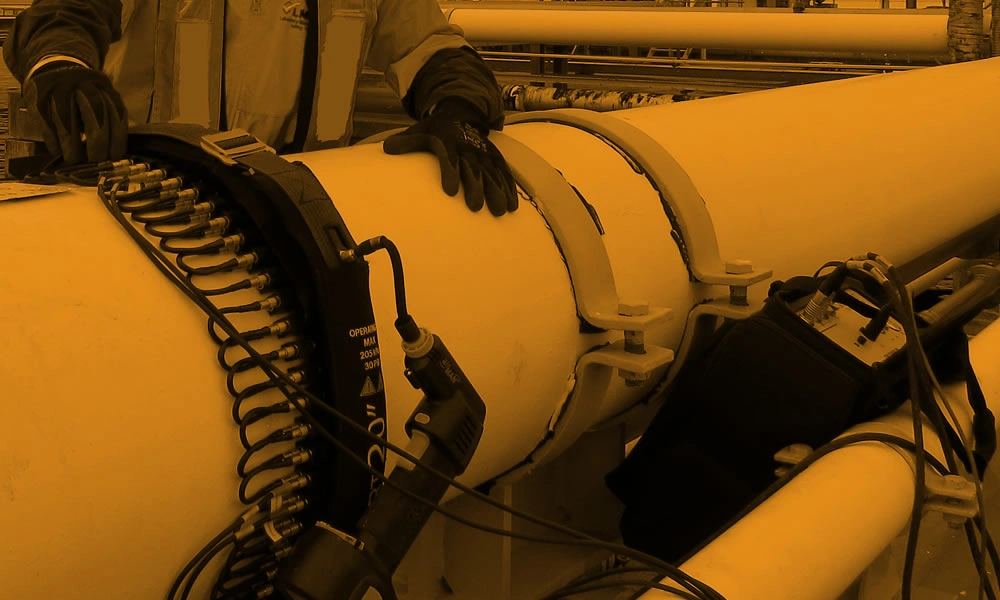

PAUT is widely used for the detection and characterization of corrosion in pipes, tanks, vessels, and other critical assets while they are in service. PAUT probes can cover a larger surface at higher speeds due to their larger footprint, resulting in significant time savings and improved resolution.

Phased array testing aids in the speed and efficiency of corrosion inspection. With fully encoded C-scan imaging, our solutions enable inspectors to be more productive and collect higher resolution data.

AQUALIS has specialized scanners and probes to provide efficient inspection options for detecting wall thickness loss caused by corrosion, abrasion, and erosion. Our solutions can also detect and differentiate mid-wall damage, such as hydrogen-induced blistering or manufacturing-induced laminations, from loss of wall thickness.

HEAD OFFICE

P.O. Box: 84711,

106, Al Midfa Building,

Al Qusais Industrial Area 4,

Dubai UAE

©2025www.aqualisgroup.com. All Rights Reserved.

©2025www.aqualisgroup.com All Rights Reserved.